GLYCERIN 995USP

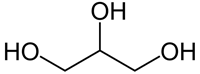

- Molecular FormularC3H8O3

- CAS No.56-81-5

SH g&c produces high-quality refined glycerin extracted from vegetable oils.

Glycerin is used to manufacture polyether polyols, alkyd resins, Green ECH, and other chemical products, as well as cosmetics, personal care products, food & beverages and pharmaceuticals.

SH g&c provides various grades of glycerin. Technical grade glycerin has 80% to 95% concentration and USP grade has high purity over 99.5%. SH g&c can meet customer’s specific requirements in terms of quality, certificate, and the origin of raw material.

Structural formular

| Item | Specification | Typical Values | Test Method |

|---|---|---|---|

| Appearance | Transparent | Transparent | USP43 |

| Glycerin Content (%) | 99.5 min | 99.6 | USP43 |

| Moisture (%) | 0.3 max | 0.07 | USP43 |

| Color (APHA) | 10 max | 4 | USP43 |

| Identification A (IR) | Conform | Conform | USP43 |

| Identification B (DEG & EG) | |||

| Diethylene Glycol | 0.1 max | pass | USP43 |

| Ethylene Glycol | 0.1 max | pass | USP43 |

| Identification C (GC) | Conform | Conform | USP43 |

| Specific Gravity (@25℃) | 1.2606 min | 1.2612 | USP43 |

| Residue On Ignition (%) | 0.01 max | Less than 0.01 | USP43 |

| Chlorides (ppm) | 10 max | pass | USP43 |

| Sulphates (ppm) | 20 max | Pass | USP43 |

| Heavy Metals (ppm) | 5 max | Pass | USP43 |

| Chlorinated Compounds (ppm) | 30 max | pass | USP43 |

| Fatty Acids & Esters (mL of 0.5N NaOH/50g) | 1 max | 0.7 | USP43 |

| Related Compounds | |||

| Individual Impurity (%) | 0.1 max | Pass | USP43 |

| Total Impurities (%) | 1.0 max | pass | USP43 |

| Item | Specification | Typical Values | Test Method |

|---|---|---|---|

| Appearance | Transparent | Transparent | KSM2708 |

| Glycerin Content (%) | 94.0 min | 94.8 | KSM2708 |

| Color (APHA) | 20 max | 15 | KSM2708 |

| Density (@20℃) | 1.2456 min | 1.2496 | KSM2708 |

| Ash Content (%) | 0.05 max | Less than 0.01 | KSM2708 |

| Acidity or Alkalinity (meq/100g) | 0.3 max | 0.04 | KSM2708 |

| Saponification equivalent (meq/100g) | 3.0 max | 1.94 | KSM2708 |

| Reducing agents | Clear | Clear | KSM2708 |

| Item | Specification | Typical Values | Test Method |

|---|---|---|---|

| Glycerin Content (%) | 80.0 min | 80.8 | KSM2708 |

| Moisture (%) | 15.0 max | 8.5 | KSM2708 |

| Ash (%) | 5.0 max | 3.6 | KSM2708 |

| MONG (%) Contains methanol content | 10.0 max | 7.1 | KSM2708 |

| Methanol (%) | 5.0 max | 3.7 | KSM2708 |

| pH | 4.0 - 7.0 | 5.6 | - |

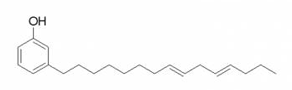

CARDANOL is the main component of Cashew Nut Shell Liquid (CNSL), a byproduct of cashew nut processing. CNSL contains Anacardic Acid and small amounts of Cardol and 2-Methylcardol.

SH g&c produces high-purity cardanol, an alkyl phenol compound, produced by decarboxylation and distillation of anacadic acid, the main component of CNSL.

Cardanol is used to manufacture surfactants, which are used in resins, coatings, friction agents, and pigment dispersants for water-based inks. With the increasing demand to replace petroleum-based materials and toxic substances, the uses of cardanol continue to expand as a diluent and intermediate for a variety of derivatives and applications.

Structural formular

| Item | Specification | Typical Values | Test Method |

|---|---|---|---|

| Appearance | - | Yellow Brown Liquid | Visual |

| Viscosity (@25℃, cPs) | 40- 70 | 50 | ASTM D445 |

| Specific Gravity (@25℃) | 0.925 - 0.940 | 0.93 | ASTM D4052 |

| Cardanol (%) | 88 Min | 92 | Assay by GC |

| Color (Gardner) | 11 Below | 9 | |

| Moisture (%) | 0.1 Max | 0.06 | ASTM D1796 |

| Flash point (℃) | 200 Above | 230 | ASTM D93 |

| Total volatile loss (@200℃, %) | 2 Max | 1 | ASTM D4140 |

| Iodine value (g/100g) | 200 Min | 230.5 | EN 14111 |

BIO-HEAVY OIL is manufactured from animal/vegetable oils, fatty acid methyl esters, and their by-products. Bio-heavy oil is an alternative to petroleum fuel for internal combustion power plants.

SH g&c provides wide range of raw materials used for Bio-heavy oil manufacturing.

| Item | Specification | Typical Values | Test Method | |

|---|---|---|---|---|

| Flash Point (℃) | Min 70 | 173 | KS M ISO 2719 | |

| Kinematic viscosity (50℃, mm2/s) | 15 ~ 80 | 32.07 | KS M ISO 3104 | |

| Micro Carbon Reisdue (wt%) | Max 5 | 1.58 | KS M ISO 10370 | |

| Sulfur (wt%) | Max 0.05 | Max 0.03 | KS M ISO 8754 | |

| Ash (wt%) | Max 0.10 | 0.028 | KS M ISO 6245 | |

| Copper Strip Corrosion (50℃, 3h) | Max 1 | 1 | KS M ISO 2160 | |

| Pour Point (℃) | Max 27 | 12 | KS M ISO 3016 | |

| Density (15℃, kg/m3) | Max 991 | 926 | KS M ISO 3675, KS M ISO 12185 | |

| Water (wt%) | Max 0.30 | 0.12 | KS M 0010 | |

| Total Acid Number (mg KOH/g) | Max 25 | 24.6 | KS M ISO 6618 | |

| Alkali Matal (mg/kg) | Na | Max 50 | 16.9 | EN 14108 |

| Ca | Max 30 | 6.16 | ASTM D7111 | |

| K | Max 50 | 7.8 | EN 14109 | |

| Iodine Value (g/100g) | Max 120 | 119 | KS M 0065 | |

| Nitrogen (wt%) | Max 0.3 | 0.05 | KS M 2112 | |

| Vanadium (mg/kg) | Max 50 | Max 0.1 | ASTM D7111 | |

| Si + Al + Fe(mg/kg) | Max 200 | 34 | ASTM D7111 | |

| Phosphorus (mg/kg) | Max 30 | 10.97 | ASTM D7111 | |

| Water and Sediment (vol%) | Max 0.5 | 0.05 | KS M ISO 3734 | |

| Gross Calorific value(kcal/kg) | Min 9,000 | 9,518 | KS M 2057 | |